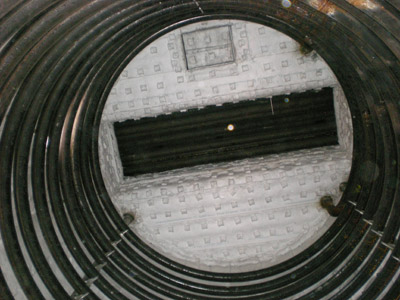

Vertical cylindrical Heaters with helical coil

These heaters are characterized by a sub-horizontal coil arrangement. The coil is arranged as a spiral (helical coil) along the cylindrical firebox wall. The burners are floor-mounted and they fire upwards. The process flow direction in the radiant coil can be either upwards or downwards, depending on the desired process flow regime.

These heaters can be designed either with or without a convection section. The main advantage of this kind of heater is the full drainability by gravity of its coil.

If compared to a standard vertical cylindrical heater, this type has a low-pressure drop, it needs a smaller plot area and provides flexibility in tube spacing, thus favoring the reduction of peak heat fluxes.

This kind of heater combines the advantage of vertical cylindrical heaters with the horizontal tube heater arrangement. Because of the limitation in the number of the coil passes that can be easily arranged as a helix in the firebox (typically 2-3), its heat duties are generally in the range of 1-10 MW.

This kind of design is typically suitable for process services such as reboilers, hot oil heaters, heat transfer medium heaters, feed preheaters, regeneration gas heaters, and light crude heaters.